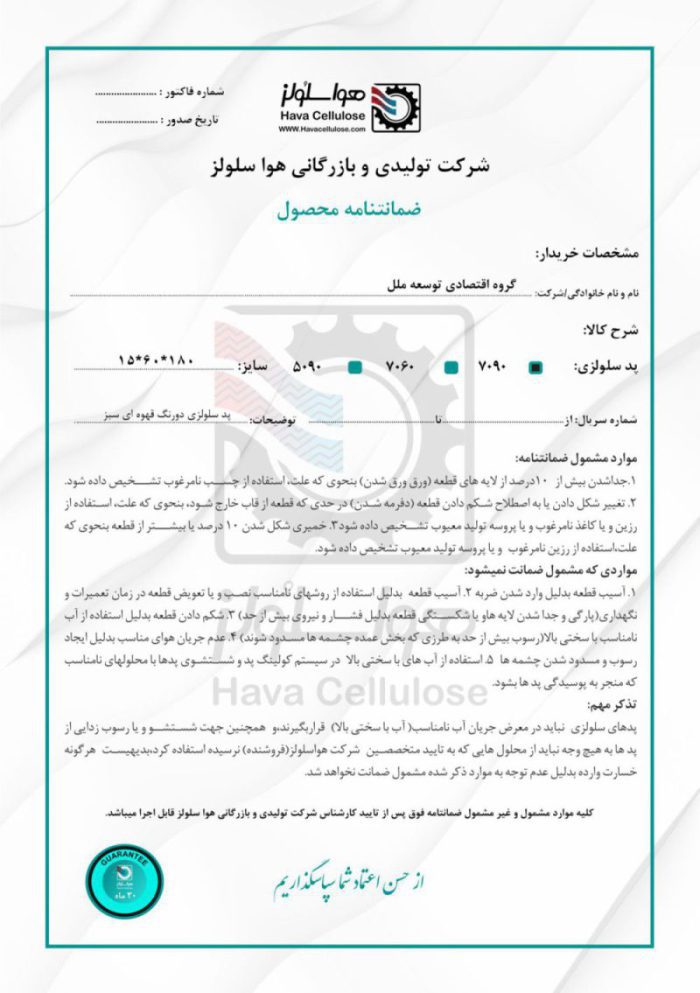

Separation of more than 10% of the layers of the part (sheet peeling) in such a way that the cause is identified as the use of poor quality glue

Changing the shape or so-called bellying of the piece (deformation) to the extent that the piece comes out of the frame

The formation of a paste of 10% or more of the piece in such a way that the cause of using low-quality resin or faulty production process is recognized

Component damage due to impact

Component damage due to the use of improper installation methods or component replacement during repairs and maintenance (tearing and separation of layers or component breakage due to excessive pressure and force)

Bellying is the bellying of the piece due to the use of inappropriate water or high hardness from excessive sediment in such a way that most of the springs are blocked

Lack of proper air flow due to sedimentation and blocking of springs

Using high hardness water in the cooling pad system and washing the pads with inappropriate solutions that lead to pad rot

The price is right

best quality

fast sending

Cellulose pad frame

In order to use the cellulose pad and install it in the desired place, we need a frame to hold the cellulose pad, which is called a cellulose pad frame. The function of these frames, in addition to keeping the cellulose pad in the cooling system, is also to increase the strength of the pad to Prevent their bending and curvature in the long term. It also collects the water in the cooling system and transfers it to the tank of the machine. These frames are produced in two types of galvanized steel and aluminum. Airsols frames with the highest quality and the best raw materials are designed in such a way that they can be easily opened and closed to clean the tank and wash the cellulose pad.

Galvanized frame

The sheets used in the production of this frame are the best type of sheets available in the market, with a high coating (point to point 2.5 microns), which has the longest useful life against moisture and the so-called rust and decay. According to the need and use of that part of the frame or the side parts related to the frame, different thicknesses of sheets have been used in the sizes of 1mm-1.25mm-1.5mm.

The design of this type of frame is taken from the design of the frame of Monterz Company, which is the first manufacturer of cellulose pads in the world and the leader in this industry, and the engineers of Air Cellulose Company tried to make optimal use of this shape of the frame while re-designing these parts precisely. in the native conditions of the country.

Aluminum frame

The aluminum frame of the cellulose pad is one of the cellulose pad frames, like the galvanized frame. Cellulose pad frames have a long life due to the fact that they do not bear any pressure during use, but the use of aluminum frames is faster and easier to install than galvanized frames, as well as the lack of deformation and deformation, as well as appropriate connections. Sealing is one of the advantages of these frames.

All intellectual and material rights are reserved for Hava cellulose.